Kanban is the world’s favourite task management methodology. The organisational system dates back to the mid-20th century when the Kanban board was first used in a production plant of Toyota. It is currently used in every task-based work and new technologies proved immensely popular. Kanban was put in place in the relevant software which makes task-based work easier – and this is not merely an ordinary board with pieces of paper stuck to it, but a table with a lot of additional functions. Kanban task management, a work organization system, dates back to the 1950s. The experts in the application of this solution claim that it allows one to increase teamwork productivity by 20-30% in a short time.

Task management on Kanban boards in different cloud-based programmes is extremely easy, effective and intuitive and it simply makes task-based work significantly easier. Which programmes for managing tasks on the Kanban board are the best and why? See for yourself.

Kanban boards in IC Project

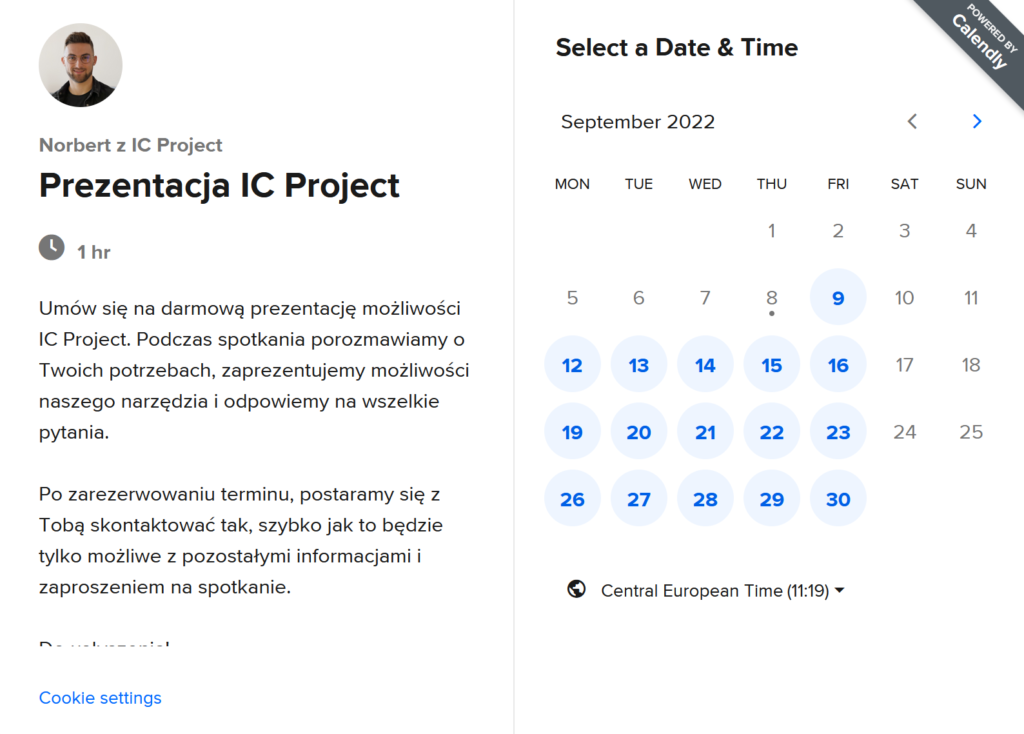

IC Project is an exceptionally intuitive task management programme, which makes your task-based work much easier daily. The tool allows you to divide all your tasks into projects and task boards, which will positively affect work organisation. The process of adding tasks has been shortened to the minimum – you just have to enter the name of the task and, as an option, set its deadline. Proper shortcuts and marking with “@” let you assign specific individuals with lightning speed.

Each Kanban board in IC Project includes 3 task statuses by default – to do, in progress and completed. However, Kanban offers full flexibility. You can design the path of the task as you please: you can add any statuses you want and change the name of the existing ones. It is you who decides what each Kanban board will look like in your task-based work.

IC Project is a very intuitive tool that is convenient in day-to-day work. This is thanks to such factors as the “drag & drop” work method, which was implemented in the programme. What is it? If you want to change the task status, you just drag the task between columns and drop it: you don’t have to search for the option to change the status; instead, you do what your brain prompts.

Task delegation works identically – you click the proper icon and a view appears where you see all members of your team. You drag the icon of a member over a task, drop it and task delegation is done. The member will also receive a proper notification at that instance (and this is yet another advantage over a colourful piece of paper ).

IC Project features a three-way notification system that informs you about new duties, reminds of upcoming deadlines and notifies you of any changes that you should be up to date with. You will always receive a notification in the system, a message in your email inbox and a direct message to your smartphone from your mobile application. Of course, every task in IC Project is a multitude of additional functions to use, e.g. the entire system of task-related comments, the option to add files, dedicated checklists, prioritisation, task cyclicity or the possibility to track work time. All these options result in the fact that you receive an extremely wide array of possibilities for your task-based work in the IC Project.

To sum up, IC Project is the best tool for managing tasks on the Kanban boards, which is the perfect blend of high functionality and ease of use. If you would like to work on tasks using an appropriate programme, IC Project will be a great choice without a doubt – also because you will find a lot of guidebooks and educational materials that will help you install yourself into this solution. However, if this wasn’t enough for you, at any time you can contact Customer Service, which is at your disposal.

Kanbanize

Kanbanize is a very interesting project management tool with a whole platform implemented, which helps manage tasks on Kanban boards. Thanks to this tool, you will have insight into task-based work, can combine planning with execution and will be able to finish specific tasks much faster. Kanbanize is a tool that might work very well in typical production work that takes over a dozen elements to complete.

The Kanban board in Kanbanize can be very elaborate: it can include several statuses, which you can manage on an ongoing basis and adapt exactly to the needs of your team and your entire business. Of course, the tool allows teamwork on the joint board. For the process to be more intuitive, the programme lets you define the core roles of each user, and so delegate tasks more smoothly.

Kanbanize means a huge dose of flexibility and a lot of customisable fields. As a result, you can adapt the task preview, the fields to be available and all other options available in predefined fields. This allows you to make the entire task-based work process custom-made for your business – there will be no standard fields: all of them will be defined by you.

Yet another feature of Kanbanize is the so-called WIP limits – Work in Progress. This is a solution that allows you to have control over the task-based work performed by your team. In each column, you can set the maximum limit of tasks that can be placed there. If the limit is exceeded, the board will display a properly visible alert and if the user would like to move a task to such a column, they will have to enter the reason for which the task has to be placed in it even though the current WIP limit is exceeded. Needless to say, this is a very interesting solution, which can be applied in advanced production work on specific and selected stages of work.

Kanbanize is a tool for managing tasks on Kanban boards, which offers a lot of interesting and advanced features. It seems that this solution is intended for businesses with high production needs – it might not be cut out for simpler task-based work, which is to be simple, pleasant and intuitive by definition. Undoubtedly, it is worth having a closer look at such a tool for task-based work in Kanban and testing out its possibilities for yourself.

Kanban Tool

Kanban Tool is a simple tool for managing tasks on the Kanban board. As the name itself suggests, all have been based on Kanban in this solution. This is software where you will not find any advanced features beyond task-based work – it might be a minus, but it might also be a plus. The programme focuses only on tasks shown in the Kanban form.

Kanban Tool is a visual tool giving you insight into the current status of your work and making cooperation and team communication easier. It offers a lot of interesting features that allow you to better control all tasks of your team. In addition, the solution was based on the “drag & drop” method, which allows moving tasks around between statuses in an easy way. Each task offers basic functions, such as prioritisation, deadline set, a system of comments or task categorisation.

A big advantage of Kanban Tool is the option to track the time spent working on tasks. In effect, you will know who devotes how much time to a specific tool. Unfortunately, it doesn’t translate further into for instance finances in the tool, which is offered by IC Project for example. A very interesting solution in Kanban Tool is the analysis of task-based work presented in the form of different charts or diagrams. It allows controlling a lot of processes that happen within task-based work visually on the Kanban board. With this solution, you will react quicker, and you will refine your processes to prevent any further delays.

To summarise, Kanban Tool is a functional tool for task-based work which is based exclusively on the well-known and generally appreciated Kanban boards. If you’re looking for a tool for simple task-based work which will present such work clearly and visually, it seems that it will be a good idea to consider Kanban Tool and test it out.

Trello

Trello is a task management tool that is very popular in the world. It owes its popularity… to its simplicity, so to speak. The programme is based on Kanban boards, which can be additionally divided into projects. It allows assigning individuals to specific tasks in these projects or on selected boards. This is a great tool for proper organisation of your work and the work of your entire team or business.

Just like every task management tool, Trello features the possibility to adapt Kanban to your own needs, meaning personalised changes in the workflow: adding new statuses or changing the current ones. All this is based on the “drag & drop” method, which is efficient in day-to-day work to a maximum. In each task, you will find a system of comments, label management, deadline adaptation and many more interesting and useful features.

This is a programme which keeps on developing and we have to admit that it looked much different several years ago compared to what we are served today. A lot of new functions appeared in Trello. One of them is the Butler function – process automation. How does this work? Butler uses natural language instructions to automate nearly every task in Trello. As a result, you can choose specific terms on which the automation will work: for instance when it should move a task to a different column, how to plan tasks or when to show deadlines and remind the entire team about them.

What’s more, Trello offers you quite a large number of ready-made templates, which are prepared for specific industries and solutions – it allows uploading the data straight away and learning the ways of organising work. You don’t have to make things from scratch and work hard – everything is ready but, let’s face it, there are no perfect solutions and you will likely have to fine-tune each template so that it matches the process carried out in your team or your business.

To sum up, it is worth adding that Trello relied on integration big time – the tool offers many interesting solutions for integration with different systems and plugins. There are over a hundred various additions available that let you streamline your working process even more. Trello is a well-known tool which will be a great fit for task-based work, there is no doubt about it. The Kanban board in Trello offers many interesting solutions as well as work automation. Before selecting the appropriate programme, you have to ask yourself whether tasks are everything you need. Trello is great for managing tasks in Kanban, but if your needs are growing, the tool might prove a little too small. Check it out for yourself and test its possibilities.

Todoist

Todoist is a task management application where working on Kanban boards is one of the possibilities. The entire tool has been designed for quick and convenient task-based work – currently, it does well in day-to-day work as well as ordinary chores, which allows you to organise your life better.

It is intended for controlling your productivity and helps you write down tasks, for instance via a mobile access through its mobile application. All tasks can land in the main view of course, but there is also an option to classify them under the appropriate projects. It all depends on how you want to work and what your needs are – the tool is flexible. The entire layout of the system is simple and versatile and the Kanban boards are fully editable, certainly. Todoist gives you the option of teamwork, where you can simply assign individuals to selected tasks. All this is also linked with a system of notifications and reminders.

Each task in Todoist has basic functions, for instance, comments, checklists, labels, priorities and appendices. In this context, systems do not differ from one another and each offers very similar options – they might only be presented differently. Todoist stands out with its option of rewards for productivity. Each task completed on time gives you the so-called Karma, which you can then control and use to do interesting analyses of your productivity. Without a doubt, this is a minor addition, but it can improve your productivity, even if just slightly, thanks to the extra motivation. A solution of that sort presents the focus of Todoist very well – that is typical task-based work.

This is a simple tool, strongly headed for task-based work, where you have a lot of interesting options to choose from. If you choose Todoist, you will see that it is a solution which supports you in your daily chores. Is it a good solution for work? It might be a little too simple, but it also depends on your requirements. Todoist is a programme for managing tasks on the Kanban boards which does not feature any advanced or complex functions.

Best Kanban task management in 2022

The Kanban method was first used to manage production processes in Toyota facilities. Today top programs for managing tasks use Kanban boards because of their benefits to supervising projects.

What is Kanban task management?

Kanban is a signboard or a plate in Japanese (literally Kan – visible, Ban – a piece of paper). Its original version relied on the circulation of product cards and served to optimize repeatable production processes. For the first time, it was applied in Toyota facilities and it aimed to coordinate the production process and supply chains to minimize the need for the storage of subassemblies.

In practice, it was accomplished by pinning cards with consumed materials to a generally available task board, which was a signal for the team delivering the given component that it is necessary to prepare its next batch. The assumed result of such a coordination of activities in individual departments of an enterprise is to reduce the need for storage of finished products, reduce shortages and increase productivity.

The Kanban method-a visible list

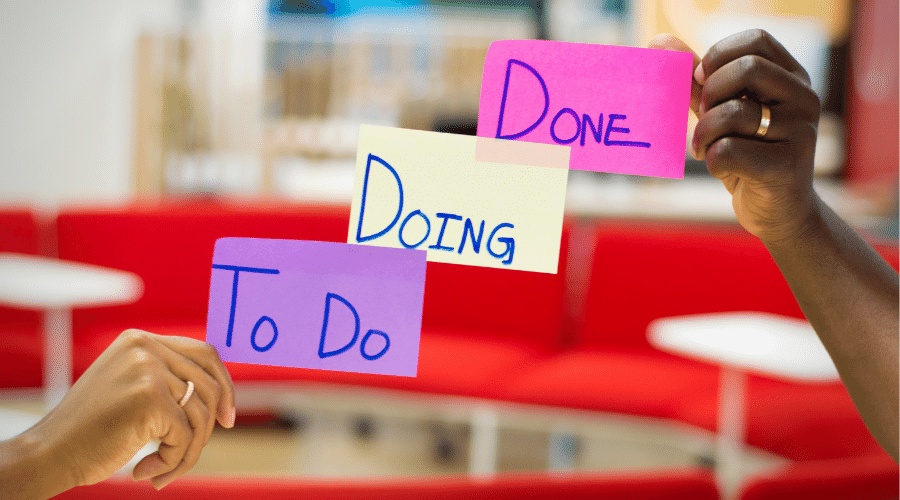

Let’s start by looking at the method itself. Kanban originates from Japan, and the word means “a visible list”, i.e., a “card” on which tasks to be performed are presented. Although this tool, which debuted in the Toyota factory, was originally used to control production, its simple rules can be successfully employed in any industry or team. In its simplest form, all you need is a large board hung in a place visible to the entire team, sticky notes, and a felt-tip pen. What does project management look like if we use Kanban? We write down all the tasks the team has to perform on sticky notes. We divide the board into three columns (in the basic version) named: “to do”, “in progress” and “completed”, and then we place the particular notes in them. The tasks are moved from one column to another after the specified criteria are met (e.g., only a task accepted by the client can be considered completed). The important thing is that the number of tasks that can be placed in one column at the same time is limited.

What makes this method powerful? It is much easier to manage tasks if they are something more than just empty phrases in our heads—if they are given a physical form. Naming and visualizing all the tasks the team has ahead of them allows them to determine the amount of work to be done. It is no surprise that it usually turns out that there are many more of them than it seemed at first. Thanks to this, the project status is always within arm’s reach and all team members know at what stage their work is. This allows us to identify potential problems quickly, before they become real threats, and to eliminate the reasons for standstills. Effect? The job is done on time, and the final product is of better quality.

Kanban Software

In the days of the Internet and dispersed teams, the Kanban system has gained its electronic counterparts. You can benefit from all the advantages of this solution in ICP, where project management is carried out using a virtual Kanban board, allowing for workflow visualization. All you have to do to change the task status or transfer it to another section is… move the “card” corresponding to it to the proper place. The columns dividing the tables are fully modifiable. They can be removed, added, or renamed. The cards themselves are also equipped with multiple practical functions. In addition to the text description, you can also add such items as checklists, comments, attachments, and color labels categorizing our activities or deadlines automatically saved in the calendar. The legible task distribution and transparency of process flow in the company provided by ICP make communication among the employees much more efficient and improve work productivity.

It’s past time you discovered the power residing in the seemingly inconspicuous cards. Kanban is a tool that provides a simple recipe for reducing task performance time, increasing the quality of provided solutions, and gaining control over the process we work in. The Kanban method is an effective method for increasing project team motivation and effectiveness.

Application of Kanban

Kanban, in its original form, is still used to optimize repeatable production processes, for instance in the automotive or electronic industry. However, dozens of its modifications have appeared over the years, aiming to answer to specific needs of enterprises and the specific nature of their production process. A range of benefits derived from using this process visualization method resulted in its adaptation to solutions outside production industries as well.

The assumptions and concept of implementation of Kanban in software engineering were presented by David J. Anderson in his book Kanban: Successful Evolutionary Change for Your Technology Business published in 2010. To manage his project, he broke it down into a range of tasks composing and divided it into three groups: to do, pending, and completed. Specific contractors are assigned to each of them, which allows easy identification and elimination of potentially problematic areas.

This also facilitates optimization of the process of project implementation and allows control over relationships between successive tasks or their internal division into even smaller units to be performed serially or in parallel. Today, such a modified Kanban is successfully used to organize project-related work in creative agencies, IT companies, architecture studios, and other entities.

Implementation of Kanban in IC Project

One of the more interesting software out there that allows the implementation of Kanban in an enterprise is IC Project. It allows transparent organization and supervision of current projects. The central part of every project is the Kanban board divided into columns with tasks pinned to it. Conventionally, three categories suggested by Anderson are available, but it is also possible to create a new one.

Tasks are placed within these categories. Each task has a range of attributes such as the title, deadlines or assigned employees, and their working time. Moreover, each task can feature a to-do list of smaller activities leading to the completion of the task, file exchange, or even a chat between the assigned individuals. A huge advantage of tasks is that they can be assigned cyclicality, which comes in handy when it is necessary to prepare reports or carry out supervising activities.

The tasks pinned to the board are handled in an exceptionally user-friendly manner by the simple drag and drop mechanism. The same method is used to assign employees to tasks or remove them and to add files necessary to complete a task or made as part of the given activity. Using built-in options, it is also possible to automatically or manually send reminders of upcoming deadlines and the content of the given working project.

Effectiveness of Kanban

Implementation of Kanban in the Toyota facilities brought an array of benefits. The stock was reduced by 75% and shortages by as much as 95%. Production went up by 25% and production space was reduced by 10%. At the same time, the surface area of warehouses and the number of employees delegated to them decreased. Such high effectiveness led to a huge interest in this method of production process organization in companies operating in various industries.

The most noteworthy benefits of using Kanban most frequently mentioned by practitioners and theorists of management are:

- Improved transparency of the project leading to a better overview of its completion status,

- Improved efficiency through ease of identification of problematic areas,

- Improved productivity through better supervision over the number and type of tasks assigned to a specific team or a specific employee,

- Better predictability of results and the dates when they are achieved.

Norbert Sinkiewicz, Head of Marketing w IC Project, underlines the importance of transparency of tasks performed as part of a project: The methods for managing tasks in Kanban are praised by our clients – it creates great possibilities for transparency and intuitive management of tasks. It allows ongoing control over the progress and status of tasks on the common board and every single task offers a plethora of additional functions waiting to be used. As a result, you always know what stage of working on tasks your team is currently at.

Does Kanban have any drawbacks?

Just like with every organization method, Kanban does have some weaknesses. First of all, its effective use requires some practice and adaptation to the specific nature of the enterprise, its orders, and the habits of its employees. This results in the simultaneous operation of several dozen types of Kanban and moving around them may prove very difficult at first, thus discouraging the implementation of this method in an enterprise.

Some features of the Kanban system may result in the fact that it will not allow such remarkable results outside extremely disciplined Japan. First and foremost, its efficient implementation requires the full involvement of all employees if we want to achieve maximum effectiveness at each stage of task performance. Any delays, even ones caused by external factors, may lead to an avalanche-like drop in the efficiency of all production departments. Fortunately, these limitations have less importance and effect on the timeliness of task performance in the project context.

Kanban in a nutshell

As a method of organization, Kanban does a great job both in production enterprises and in entities relying on projects. Due to its ease of modification and a multitude of variants, it is easy to adapt to the specific activities of the given enterprise, increasing the transparency of the projects being carried out. Breaking them down into smaller tasks to which specific employees, deadlines, and guidelines are assigned makes the supervision over the performance of the projects much simpler. It is also easier to respond to cropping up problems.

Contemporarily, Kanban is usually implemented in the form of an online computer program, e.g. IC Project. This allows easy management of and communication with the employees working in the head office and those working remotely. Kanban task management gives the possibility of assigning them to tasks, communication between all employees assigned to the given activity, easy exchange of files, or a reminder system makes the completion of projects in an enterprise flow seamlessly – at least in organizational terms.